The required energy in inch ton.

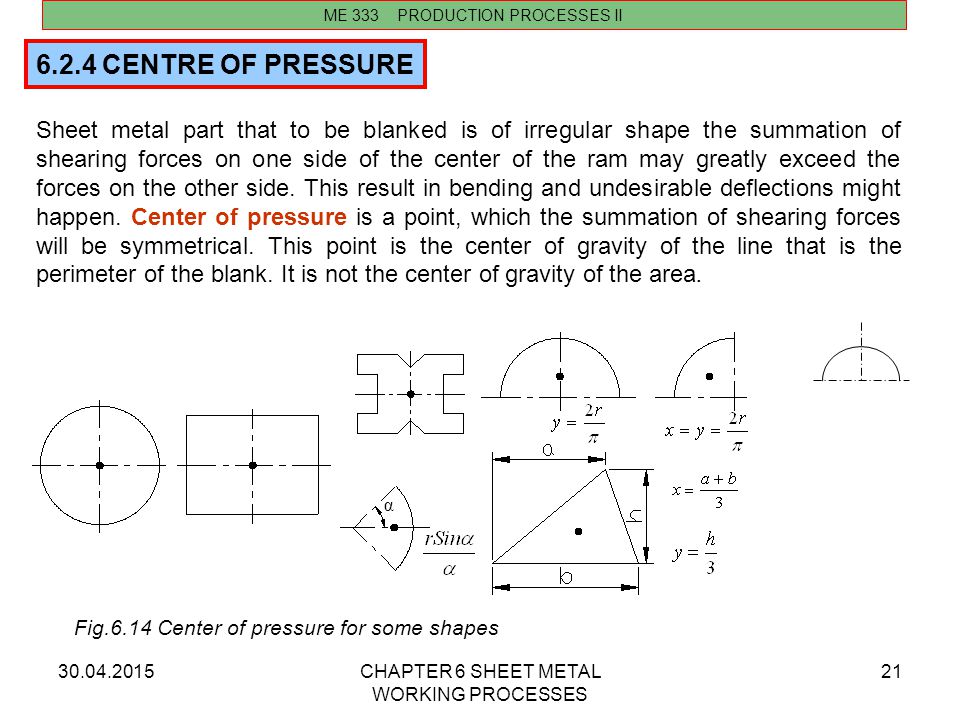

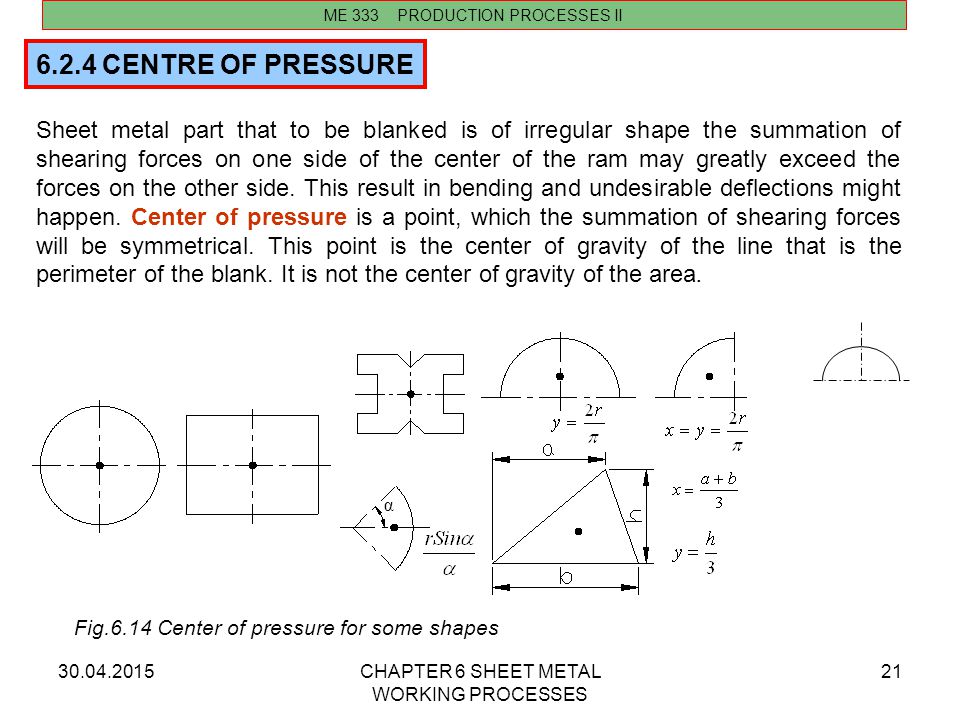

Center of pressure in sheet metal.

The follow web pages contain engineering design calculators that will determine the amount of deflection and stress a flat plate of known thickness will deflect under the specified load and distribution.

M d 24 in x 3 ft aluminum sheet metal.

Centrifugal casting is both gravity and pressure independent since it creates its own force feed using a temporary sand mold held in a spinning chamber.

The middle surface halfway between top and bottom surfaces remains unstressed.

Here analytical method to find center of pressure in press tool is described.

Sheet metal working concept of center of pressure.

This prepares the data for the second calculation.

Metal is poured into the center of the mold at its axis of rotation.

Lead time varies with the application.

Hillman 24 in x 24 in cold rolled steel solid sheet metal.

Sheet metal forming with hydraulic counter pressure in japan k.

First the sheet metal pat draw on autocad screen as shown in figure 2.

Nakagawa l japan received on march 4 1987 accepted by the editorial committee 5 i i l 1 the sheet metal forming method with hydraulic counter pressure which makes use of hydraulic counter pressure generated through the penetration of the punch into the die cavity.

At other points there are biaxial stresses in the plane of the plate.

Request pdf center of pressure determination of sheet metal blank part using computer facilities the cutting force of the shearing cut blanking die must be concentrated in a point called.

Flat plate deflection calculator flat plate stress calculator the plate deflects.

Due to inertial force the liquid metal is thrown out toward the periphery.

The center of pressure calculated and defined automatically using a special code written by autolisp under autocad 1.

Engineering calculators menu engineering analysis menu.

Submitted by prof.

Flat plates stress deflection equations and calculators.

Insufficient energy is a common cause of press jams at bottom dead center bdc.